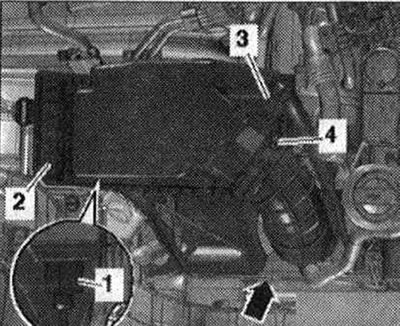

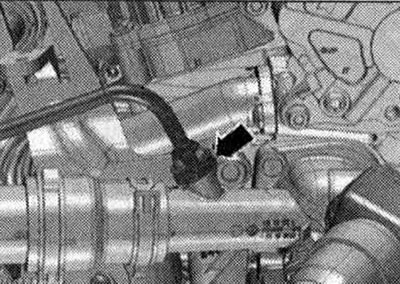

Disconnect el. Plug connection -3- for differential pressure sender -G505-. Unscrew the bolt -2- and release the hoses -1- from the holder. Move differential pressure sender -G505- to rear.

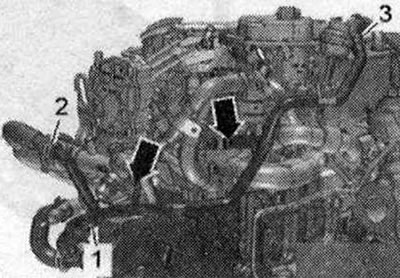

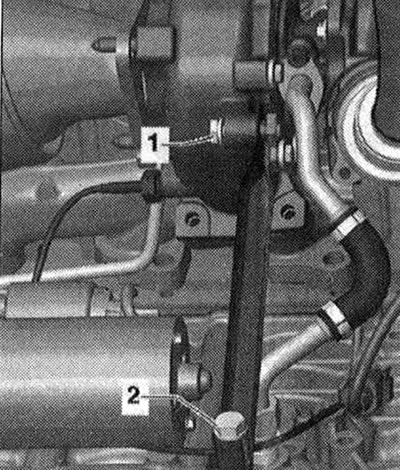

Release the bundle of emails. wires -arrow-. Unscrew the nuts -1- and remove the holder -2-.

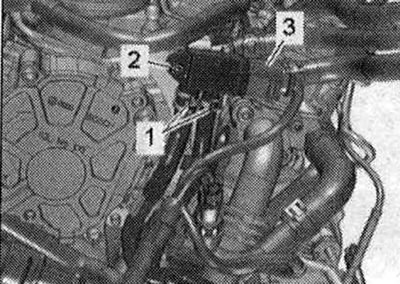

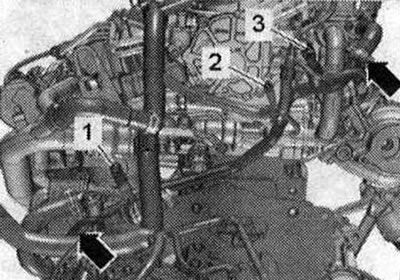

Unscrew the bolt and nut -arrows-. Remove the coolant hose by loosening the hose clamp -3-. Push the rear right cooling system pipe to the side. -Pos. 1, 2 - do not take into account.

Disconnect el. plug connection -3-. Unscrew bolt -1 -. Remove the coolant hoses from the coolant pipe by loosening the hose clamps -arrows-. Place the differential pressure sensor back. -Pos. 2- do not take into account.

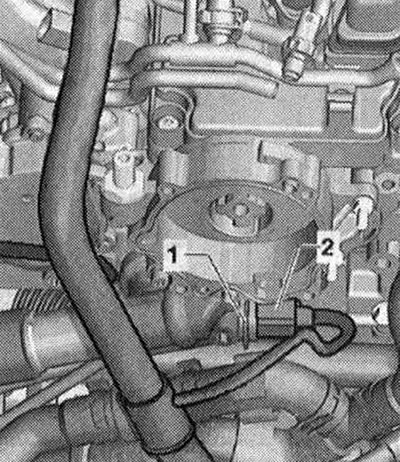

Disconnect el. Plug connection -2-coolant temperature sensor -G62-. -Pos. 1-ignore.

Disconnect el. plug connection -4-.

Unscrew the oil dipstick guide tube bolt -1-. Disconnect el. Plug connection -3- of the throttle valve control unit -J338-. -Pos. 2- do not take into account.

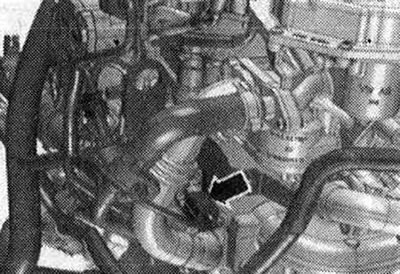

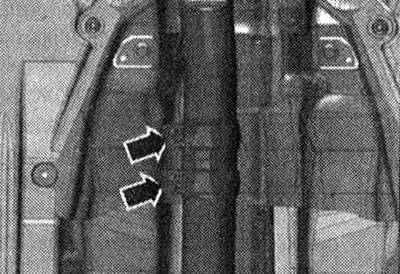

Remove the cylinder head cover. Remove the cooling system line by unclamping the mounting brackets -arrows-.

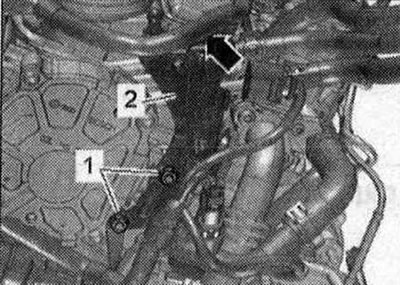

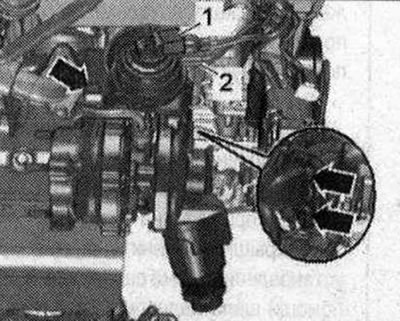

Loosen turbocharger bolt -1-. -Pos. 2- do not take into account.

Loosen the clamping sleeve -arrows-.

Unscrew nuts -arrows- from turbocharger. -Pos. 1,2 - do not take into account.

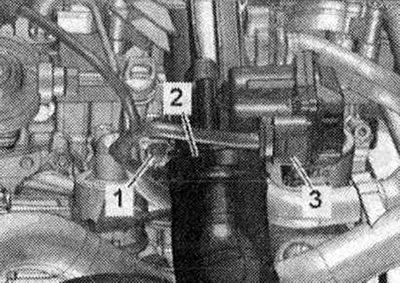

Release the bundle of wires on the cylinder head. Remove bolts -1- and -3- from the exhaust gas recirculation radiator. -Pos. 2- do not take into account.

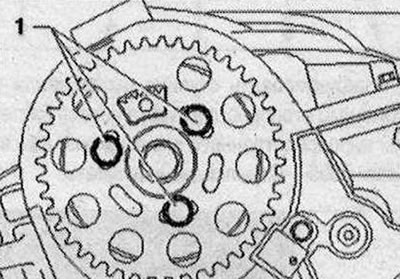

Unscrew bolts -1- and remove camshaft timing belt gear.

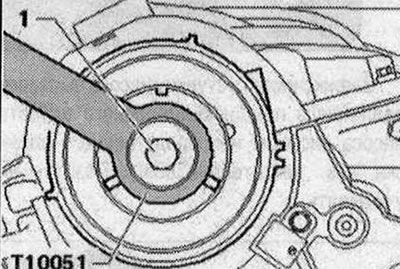

Unscrew the camshaft hub bolt -1- and hold it with the counter support -T10051-. Unscrew the bolt approximately 2 turns.

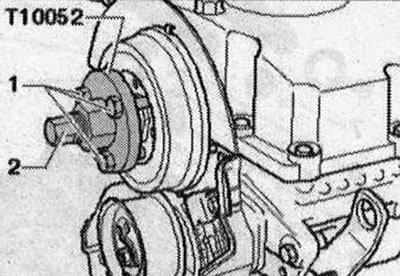

Place the puller -T10052- on the camshaft hub and screw the bolts -1 - into the hub. To remove the camshaft hub, screw in the bolt -2- and hold it by the hexagon (by 30) puller Remove the hub from the camshaft cone.

Unscrew bolt -arrow- for rear toothed belt guard.

Unscrew the Hall sensor bolt -G40- -arrow- and place the Hall sensor -G40- to the side.

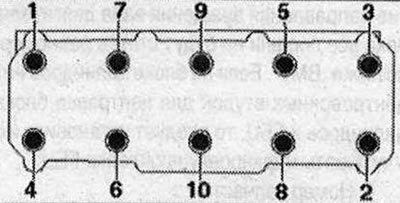

Loosen the cylinder head bolts in the sequence -1...10-. A second mechanic is required to remove the cylinder head. Remove the timing belt tension roller when removing the cylinder head from the locating pin.

Release the cylinder head backwards from the rear toothed belt guard and at the same time remove the tension roller. When doing this, be careful not to damage the oil drain line of the turbocharger. Position the cylinder head so as not to bend the oil drain line. If necessary, place a wooden block under the exhaust manifold. Risk of damage to the glow plug rods when installing the cylinder head. A removed cylinder head with installed glow plugs must not be placed on the contact surface, since the glow plug rods slightly protrude beyond the contact surface. The Audi Q5 with the 2.0l 4V Common Rail TDI engine uses exclusively steel glow plugs.

Installation

Carefully! Risk of damage to the seal. surfaces. Carefully remove any remaining sealant from the cylinder head and cylinder block. Do not allow long scratches or burrs to form. Risk of damage to the cylinder block. There should be no oil or coolant in the blind holes of the cylinder head mounting bolts. Danger of cylinder head gasket leakage. During repairs, carefully remove any remaining sealant from the cylinder head and cylinder block. Do not allow long scratches or burrs to form. Carefully remove residues after sanding and sanding. The new cylinder head seal should be removed from its packaging immediately before installation. To prevent damage to the silicone layer and the grooves of the cylinder head gasket, the gasket must be handled with extreme care. Risk of damage to open valves. When installing an exchange cylinder head, the plastic base should be removed to protect the open valves only when it is in direct contact with the cylinder head. Risk of damage to valves and piston crowns after working on the valve mechanism. To ensure that no valve comes into contact with the cylinder head during operation, carefully turn the crankshaft at least 2 turns.

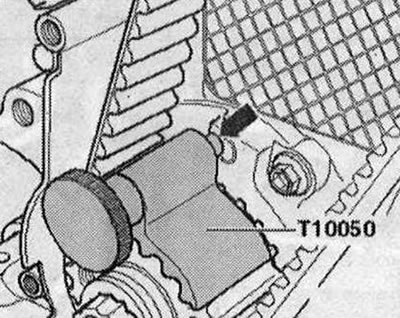

Replace bolts that were overtightened. Replace self-locking nuts, lip seals, gaskets and seals. rings. Modifications to the cylinder head of TDI engines are prohibited. If a cylinder head from an exchange stock is installed, the contact surfaces between the rocker arm and the camshaft bearing housing should be lubricated. Secure all hose connections with hose clamps of the appropriate series. After replacing the cylinder head or cylinder head gasket, the coolant and oil must be completely replaced. Before installing the cylinder head, remove the crankshaft stop -T10050- and turn the crankshaft against the direction of rotation of the engine shaft until all pistons are evenly lower "TDC". If there are no centering bushings on the cylinder block for centering the cylinder block and cylinder head, then they should be installed. Observe the markings on the cylinder head gasket.

- 1. Part number

- 2. Holes

- 3. ignore

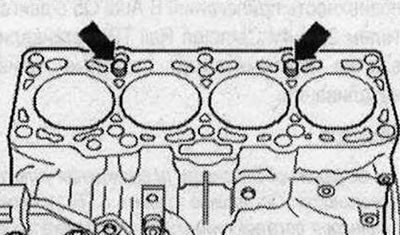

After replacing the cylinder head gasket or cylinder head, select a new cylinder head gasket according to the number of holes in the old gasket. If parts of the crank mechanism have been replaced, then a new cylinder head gasket should be selected according to measurements of the protrusion of the pistons in the position "TDC". Place the cylinder head gasket on the centering sleeves -arrows- in the cylinder block. Mounting position of the cylinder head gasket: marked "top" or the spare part number for the cylinder head.

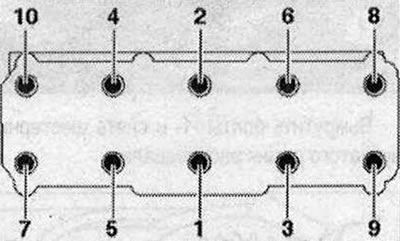

Insert the cylinder head with the pin bolt of the toothed belt tension roller into the recess of the toothed belt guard from the rear and at the same time push the tension roller. Make sure that the wire to the Hall sensor -G40- is routed correctly. Install the cylinder head. Install the cylinder head bolts and screw them in by hand until they stop. Tighten the cylinder head bolts. Install the rear timing belt guard, hub and camshaft timing belt sprocket.

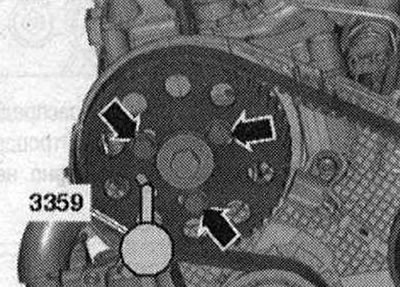

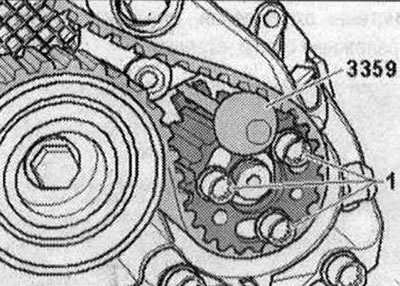

Secure the camshaft hub using the diesel direct injection pump locking pin. engine -3359-. -Arrows- ignore.

Secure the high pressure pump hub using the diesel direct injection pump locking pin. engine -3359-. -Pos. 1- do not take into account.

Rotate the crankshaft in the direction of engine rotation until the crankshaft stop pin -arrow- -T10050- engages the seal when rotating. flange. Install timing belt (adjust timing timing).

Installation is in reverse order, observing the following. Install the cylinder head cover. Install the poly V-belt. Install the rear coolant pipe. Install the turbocharger. Electrical connections and laying. Install the oil dipstick guide tube. Connect the air hose using threaded clamps. Install the rear right coolant pipe. Install differential pressure sensor -G505-. Install the left upper coolant pipe. Install the air housing. filter. Install the front wall of the drainage box. Change the oil. Replace coolant.

Visitor comments