Place the vehicle on a lift. Remove the wheels. Remove the coil springs. Remove the exhaust system resonator.

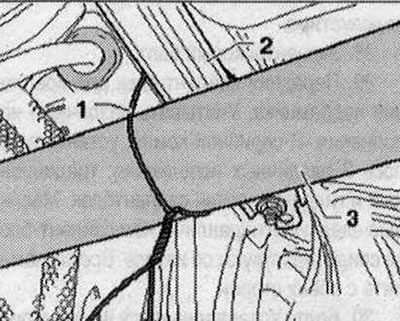

Applies to vehicles with all-wheel drive: Disconnect the propeller shaft from the rear final drive. Secure the propeller shaft -3- with wire -1- to the body -2-. Move the rear propeller shaft pipe as far as possible in the direction of the gearbox.

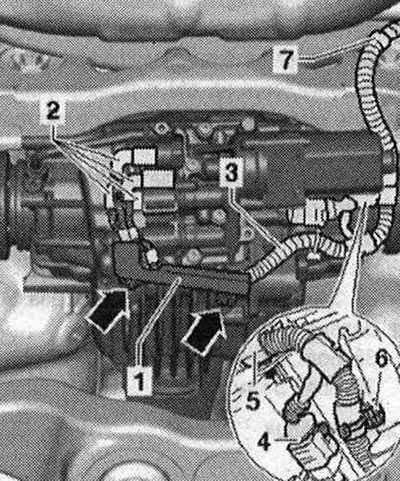

On vehicles with a sports differential, unscrew the bolts -arrows- and remove the bracket -1- from the rear final drive.

Mark the connector -2 of the oil pressure and temperature sensor on the clutch valves. Disconnect the connector -2 of the oil pressure and temperature sensors from the clutch valves. Then disconnect connector -4- from all-wheel drive pump -V415-. Finally, disconnect the wiring harness -3- from the final drive and subframe -5...7- and tie it up.

All

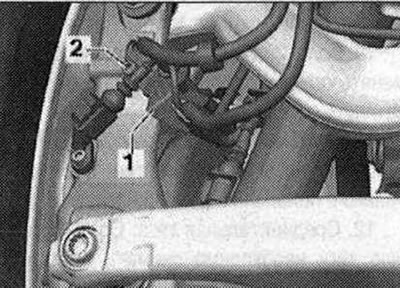

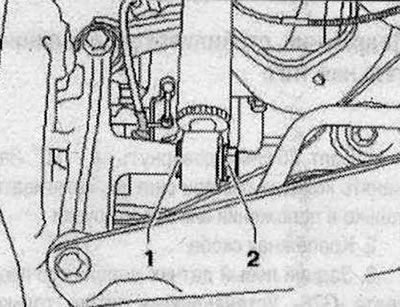

Unscrew the bolt -2- on the right and left and remove the bracket -1- with wires.

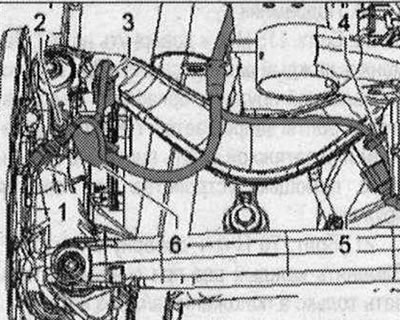

Unlock and disconnect the connector -1 of the rear left speed sensor -G46- and the rear right speed sender -G44-. Unlock and remove connectors -3- of the electromechanical parking brake on the right and left. Unscrew the bolt -2- on the right and left and remove the bracket -6- with the wire. Disconnect connector -5- from the rear left ride height sensor -G76- and, if equipped, from the right rear ride height sender -G77- and remove it. Unfasten wiring harness -4- on left and, if present, on right and pull out.

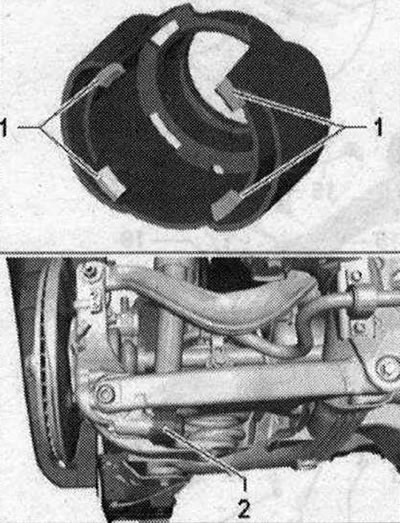

On vehicles with electronic damping control, disconnect the connector on the bumper and release the wiring harness. Unlock the locking tabs -1- and remove the stone guard -2-.

Unscrew the bolt -2- and remove the washer -1-.

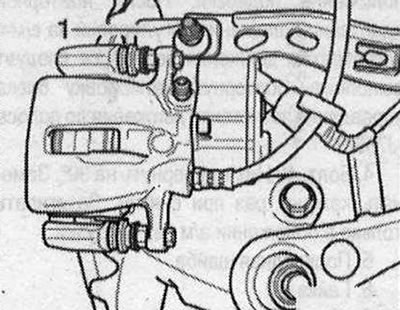

Disconnect bolt connection -1-. Remove the brake. caliper Move the caliper past the suspension elements and secure it to the body so that the weight of the caliper does not put pressure on the brake. hoses or lines, which may damage them. Screw the upper wishbone to the hub assembly -1 - by hand.

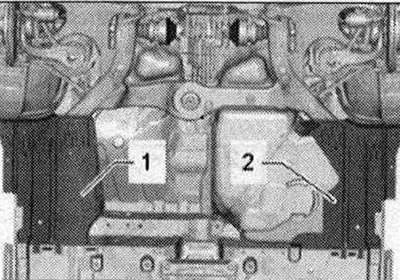

Remove cover -1- and -2-. Remove the fairings from the wheels.

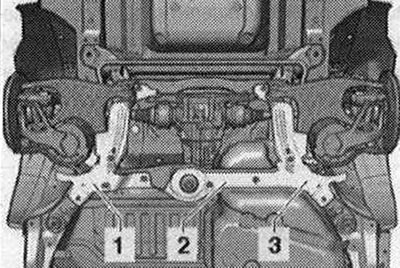

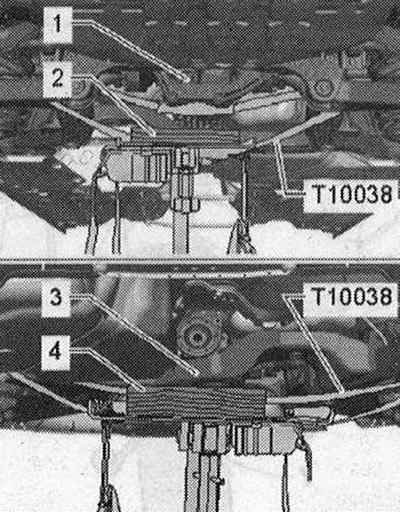

Remove stone guards -1-, -2- and -3-, if fitted. Place the tilting mechanism with universal gearbox mount -VAG 1359/2- under the subframe and secure it with the tensioning belt -T10038-. Place (in the presence of) under the rear final drive -1- a suitable wooden block -2-. Support the subframe at the front with a suitable piece of wood -4- under the cross member -3-. Loop the tension belt -T10038- around the subframe below the drive shaft and guide it behind the rear gearbox.

Route tensioning belt -T10038- under universal transmission mount VAG 1359/2- and tighten it.

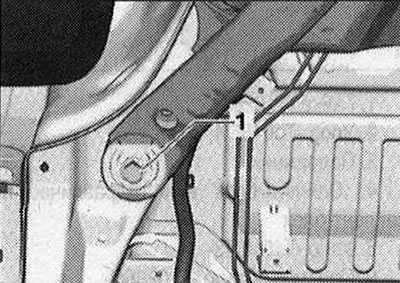

Remove bolt -1- on left and right.

Unscrew the bolts -arrows-.

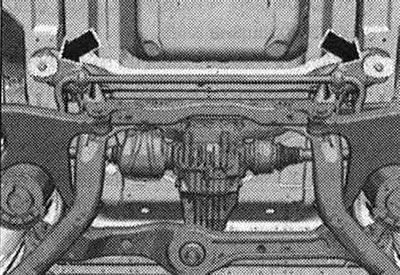

Before lowering the subframe, check that all electrical connections are complete. wires are disconnected or removed. Carefully lower the subframe with attached parts. At the same time, pay attention to the brake. calipers and brakes highways.

Installation of the subframe assembly with attached parts

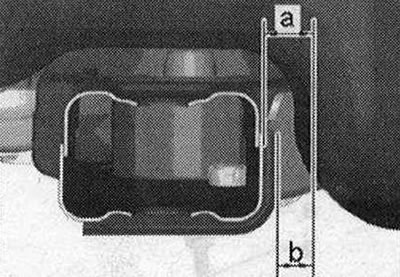

Install in reverse order. In this case, tightening torques must be taken into account. Silent blocks have a limited working range of twisting. Therefore, wheel suspension bolts should only be tightened when the vehicle is in the no-load or standard suspension position. Raise the wheel support with the suspension in static position on vehicles with coil springs. The holes of the subframe supports must be located in the center of the mounting points on the body. Align the subframe with the fuel. tank so that dimension -a- for vehicles without stone protection is 19 mm, and dimension -B- for vehicles with stone protection is 14 mm.

Install coil springs only after the subframe bolts have been tightened to the specified torque. Tighten the wheel. It is necessary to adjust the wheel alignment angles.

Visitor comments