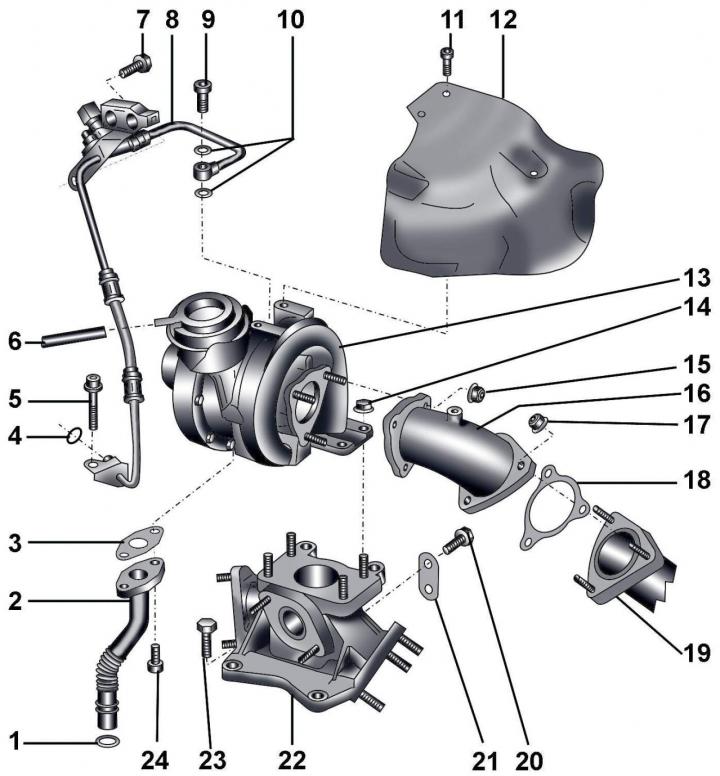

Pic. 5.3–2. Turbocharger: 1 - sealing ring; 2 - oil return pipe to the cylinder block; 3 - gasket; 4 - sealing ring; 5 - bolt, 10 Nm; 6 - hose to the vacuum chamber to control the increase in pressure; 7 - bolt, 22 Nm; 8 - oil supply pipe from the oil filter bracket; 9 - hollow bolt, 15 Nm; 10 - sealing rings; 11 - bolt, 10 Nm; 12 – thermal protection screen; 13 - turbocharger; 14 - nut, 22 Н·м; 15 - nut, 22 Nm; 16– elbow of the exhaust manifold for fastening the turbocharger; 17 - bolt, 25 Nm; 18 - gasket; 19 - intake exhaust pipe with a converter; 20 - bolt, 22 Nm; 21 - rack for an intermediate transition element; 22 - transition element; 23 - bolt, 22 Nm; 24 - bolt, 10 Nm

The power that an engine can develop depends on the amount of air and fuel that enters the engine's cylinders. To increase engine power, it is necessary to increase the air and fuel supply. Supplying more fuel will have no effect until there is enough air for combustion. Otherwise, an excess of unburned fuel is formed, which leads to overheating and increased smoke in the engine. To increase the amount of air supplied to the engine, a turbocharger is used, which compresses the air entering the combustion chamber (pic. 5.3–2).

The turbocharger consists of a centrifugal supercharger wheel and a turbine connected to each other by a common rigid axle. Both of these elements rotate in the same direction at the same speed. The energy in the exhaust gas flow, which is not used in conventional engines, is converted into torque, which drives the turbocharger. Exhaust gases leaving the engine cylinders are at high temperature and pressure. They accelerate to high speed and interact with the blades of the turbine, which converts kinetic energy into mechanical rotational energy. Energy conversion is accompanied by a decrease in the temperature and pressure of the exhaust gases. The turbocharger sucks air through the air filter, compresses it and delivers it to the engine cylinders. The amount of fuel that can be mixed with air can be increased, allowing the engine to develop more power.

For turbocharger lubrication engine oil supplied under pressure through a special pipeline.

Since the turbocharger operates at high speed, care and cleanliness must be observed: dirt entering the turbocharger can damage it.

Warning: Before disconnecting any elements from the turbocharger, thoroughly clean them of dirt. To protect against contamination, place the elements removed from the turbocharger in a sealed container, close the air channels of the turbocharger.

An intercooler is installed between the turbocharger and the intake manifold, which reduces the temperature of the air supplied to the engine. Cooling the air increases the power of the engine, as the oxygen content in cold air increases due to its higher density.

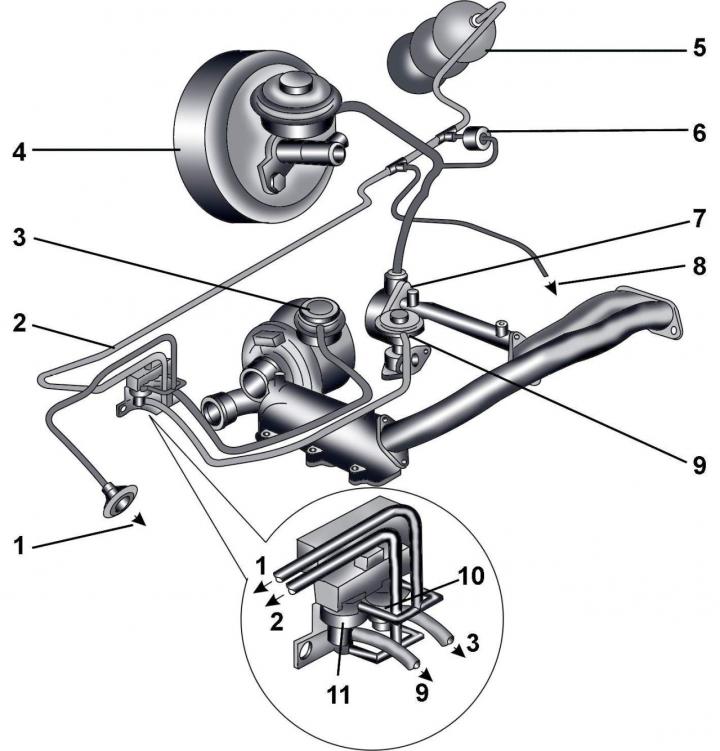

Notes: The vacuum reservoir is located at the front of the vehicle under the protection of the wheel arch.

Pic. 5.3–1. Elements of the control system for increasing the pressure of the air entering the engine: 1 - to the breather on the air filter housing; 2 – a vacuum hose to the vacuum reservoir or the vacuum pump; 3 - vacuum hose from the high pressure solenoid valve; 4 - vacuum brake booster; 5 - vacuum reservoir; 6 - one-way valve; 7 – vacuum pump; 8 - to the intake manifold valve switch N239; 9 - a vacuum hose from the N18 valve to the mechanical valve of the exhaust gas recirculation system; 10 - solenoid valve for pressure increase control N75; 11 - EGR valve N18

Pay attention to the installation position (light side / dark side), shown in fig. 5.3–1.

Withdrawal

Turn off the ignition and disconnect the wire «masses» from the battery.

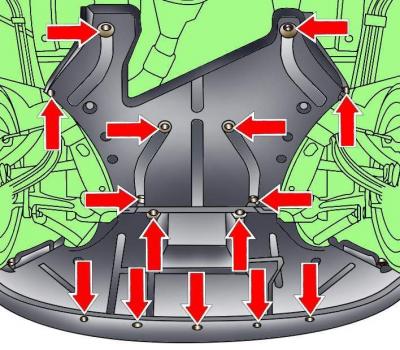

Pic. 5.3–3. The location of the fastening latches of the lower mudguard of the engine compartment

Release the clips and remove the rear section of the lower mudguard of the engine compartment (pic. 5.3–3).

Unscrew the bolt of fastening of a reception exhaust pipe on a transitional element.

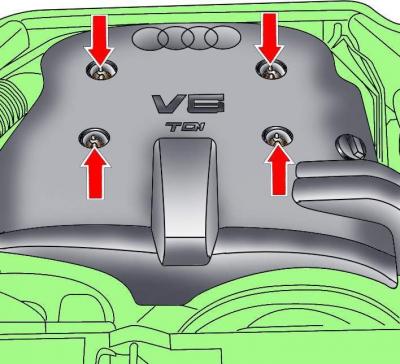

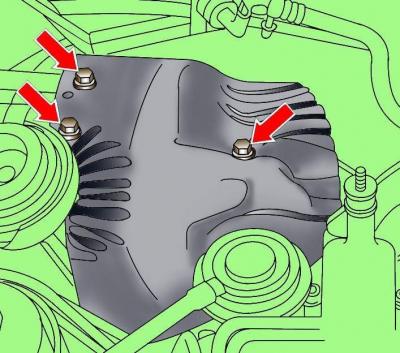

Pic. 5.3–4. Location of engine cover screws

Loosen the screws and remove the engine cover (pic. 5.3–4).

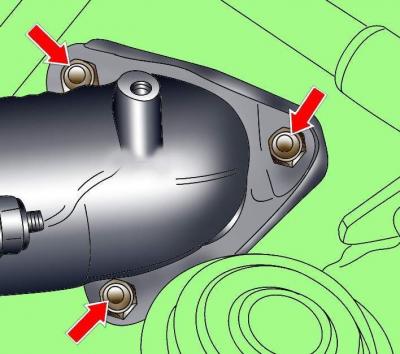

Pic. 5.3–5. The location of the bolts for securing the heat shield above the turbocharger

Unscrew the bolts and remove the heat shield above the turbocharger (pic. 5.3–5).

Unscrew the bolts securing the exhaust pipe to the turbocharger (pic. 5.3–6).

Pic. 5.3–6. Arrangement of bolts of fastening of a reception exhaust pipe to a turbocharger

Move the front exhaust pipe back and down.

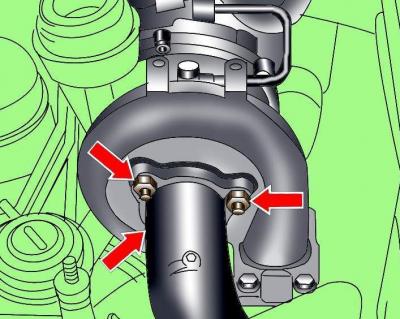

Pic. 5.3–7. An arrangement of nuts of fastening of a knee of a final collector to a turbocharger

Unscrew the nuts securing the exhaust manifold elbow from the turbocharger (pic. 5.3–7).

Loosen the clamps and remove the air pipe from the air filter.

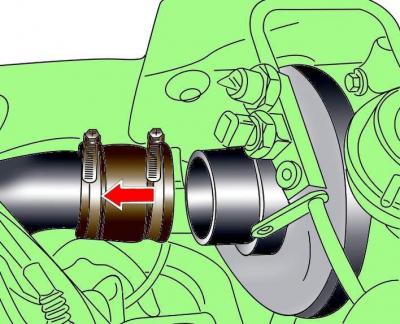

Pic. 5.3–8. Fastening pipes to the turbocharger

Loosen and remove pipes from turbocharger (pic. 5.3–8).

Disconnect the hose from the vacuum boost control chamber.

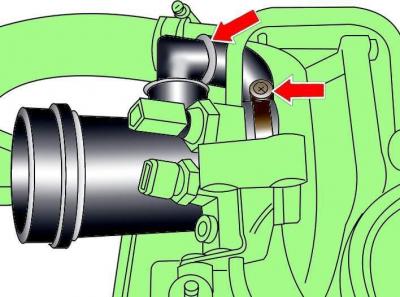

Pic. 5.3–9. Removal from a turbocharger of an air final branch pipe

Loosen the clamps, remove and move the air outlet pipe away from the turbocharger (pic. 5.3–9).

Release the clips, remove the fuel lines from the oil line bracket and move them to the side.

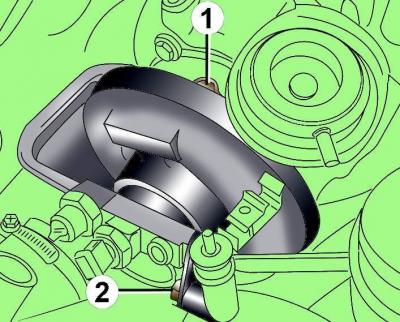

Pic. 5.3–10. Attaching the oil line to the turbocharger (1) and intake manifold (2)

Disconnect the oil line from the turbocharger and intake manifold (pic. 5.3–10).

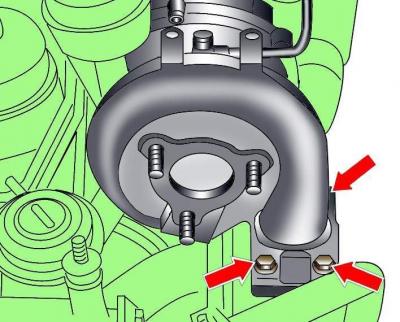

Pic. 5.3–11. Arrangement of bolts of fastening of a turbocharger to a transitional element

Unscrew the four bolts securing the turbocharger to the adapter and remove the turbocharger (pic. 5.3–11).

Cover the oil supply hole in the engine block with a clean rag.

Installation

Installation is carried out in the reverse order of removal, taking into account the following.

Replace all O-rings, gaskets and self-locking nuts.

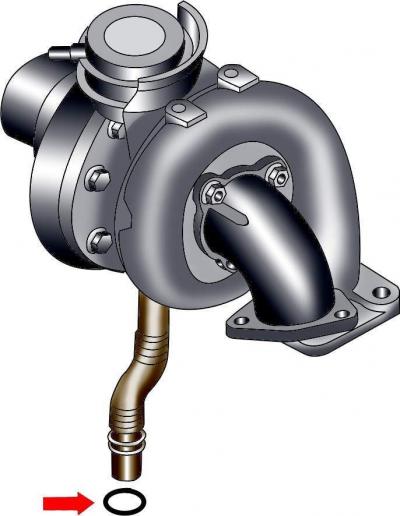

Pic. 5.3–12. The location of the O-ring of the oil return pipe from the turbocharger

Check that the O-ring of the oil return pipe from the turbocharger is not damaged (pic. 5.3–12).

Fill the turbocharger with oil through the oil feed tube hole.

After installing the turbocharger, start the engine and let it idle for 1 minute, this will ensure reliable lubrication of the turbocharger.

Check engine oil level.

Visitor comments