Attention. Never lower the vehicle on wheels with one or both drive shafts removed, as this will damage the wheel bearings. If it is necessary to install the vehicle on wheels and move it with the drive shafts removed, install the outer drive shaft joints instead of the drive shafts and tighten the joint mounting bolts to 50 Nm.

With the car standing on wheels, loosen the bolts securing the outer hinges of the drive shafts to the front wheel hubs.

Paint mark the position of the front wheels in relation to the hubs. This is necessary to reinstall the wheels in their original position, as a result of which their balance is maintained. With the vehicle on wheels, loosen the front wheel bolts.

Raise the front of the car and secure it on stands.

Unscrew bolts and remove forward wheels.

Unscrew bolts of fastening of external hinges of power shafts to naves of forward wheels.

Remove bolts 1 (pic. 7.5), fastening the internal hinges of the drive shafts to the flanges of the gearbox drive.

Remove the ABS speed sensor wire from the bracket on the brake caliper (see fig. 7.5).

Unscrew nut 1 (pic. 7.6), remove the bolt and, by pulling upwards, remove the upper transverse arms 2 from the steering knuckle.

Attention. Do not expand the grooves in the steering knuckle with a screwdriver or other tool. Do not unscrew the bolts securing the tie rod to the steering knuckle, otherwise it will be necessary to adjust the angles of the front wheels 3 and 4 (pic. 7.6).

Tilt the top of the steering knuckle to the side (arrow, fig. 7.6).

Remove the drive shaft from the vehicle.

Installation

Install the drive shaft to the vehicle.

Screw in the bolts securing the drive shaft to the gearbox flange and, diagonally, tighten the M8 bolts to 40 Nm and the M10 bolts to 80 Nm.

Screw in and torque-tighten the bolts securing the driveshaft constant velocity joint to the gearbox flange.

Tightening torques:

- bolts M8 - 40 Nm;

- bolts M10 - 50 Nm.

Screw in the new driveshaft-to-hub bolt, tightening it firmly at this point.

Install the upper transverse arms against the stop in the steering knuckle and secure them with a bolt and nut, tightening them with a torque of 40 Nm (pic. 7.6).

Attach the ABS sensor wire to the brake caliper bracket.

Apply a thin layer of grease to the shoulder of the hub that centers the wheel disc. Install the wheel according to the previously marked marks and secure it with bolts. Lower the vehicle and tighten the wheel bolts to 120 Nm.

Finally tighten the new bolt securing the drive shaft to the hub.

Tightening torques:

- bolts М14-115Н-М + tighten by 180°;

- M16 bolts - 190 Nm + tighten by 180°.

Attention. Bolt of fastening of a power shaft tighten only on the car standing on wheels.

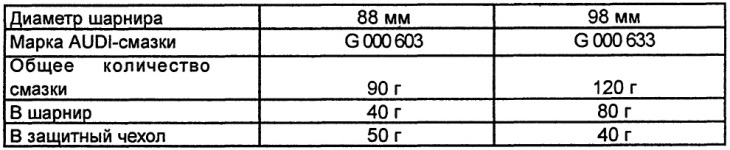

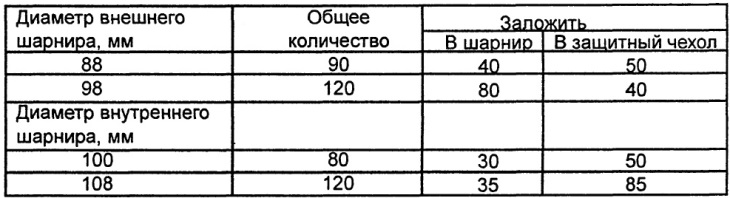

Amount of grease to fill the outer joint of the drive shaft

Attention. For hinges of different diameters, it is necessary to use different brands of grease.

Quantity of AUDI grease G 000 603 for filling drive shaft joints

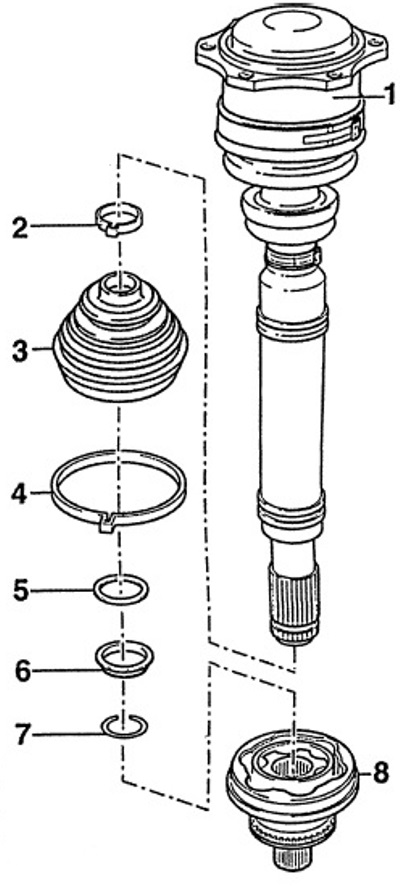

Pic. 7.19. Drive shaft with tripod joint

1 - drive shaft with internal hinge Tripoid,

2 - collar,

When installing, you must use a new clamp.

3 - protective cover,

It is necessary to check for the absence of cracks, abrasions and tears.

4 - collar,

When installing, you must use a new clamp.

5 - washer,

The concave side of the washer must rest against the thrust ring.

6 - plastic ring,

The side with the smaller diameter should face out.

7 - retaining ring,

At installation it is necessary to use a new lock ring. Before installing the hinge, the retaining ring is installed in the groove of the drive shaft.

8 - external constant velocity joint

In case of malfunction, it is replaced entirely. Depending on the engine/gearbox, 88 mm or 98 mm diameter joints are used. When installing on the drive shaft, use a plastic mallet to drive the joint until it is secured with the circlip.

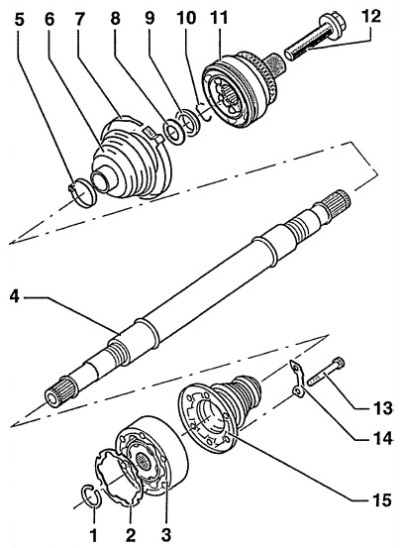

Pic. 7.20. Drive shaft with ball joint.

1 - retaining ring,

Removal of a lock ring is made with use of round-nose pliers.

2 - gasket,

When installing, a new gasket must be used. Remove the protective film from the gasket and stick the gasket to the hinge.

3 - internal hinge of equal angular velocities,

Depending on the engine/gearbox, 100 mm or 1088 mm diameter joints are used.

4 - drive shaft,

5 - clamp,

When installing, you must use a new clamp.

6 - protective cover,

It is necessary to check for the absence of cracks, abrasions and tears. Before installing the smaller protective boot clamp, bleed air from under the protective boot.

7 - collar,

When installing, you must use a new clamp.

8 - washer,

When installing, the concave side of the washer must rest against the thrust ring.

9 - thrust ring,

10- retaining ring,

At installation it is necessary to use a new lock ring. Before installing the hinge, it is necessary to install the retaining ring in the groove of the drive shaft.

11 - outer hinge of equal angular velocities,

Depending on the engine/gearbox, 88 mm or 98 mm diameter joints are used. The hinge is replaced as an assembly. When installing on the drive shaft, use a plastic mallet to drive the joint until it is secured with the circlip.

12 - bolt,

When installing, a new bolt must be used. When tightening the bolt, the vehicle must be on its wheels.

Tightening torques:

- Bolt M14 - 115Nm + tighten by an angle of 180°;

- Bolt M16 - 190 Nm + tighten by an angle of 180°.

13 - bolt,

Tightening torques:

- Bolt M8 - 40 Nm;

- BoltM10 - 80 Nm.

14 - plate,

15 - protective cover of the hinge with a flange,

There is an air outlet. It is necessary to check for the absence of cracks, abrasions and tears. Before assembling the hinge, apply a thin coat of D3 AUDl Sealant to the flange.

Visitor comments