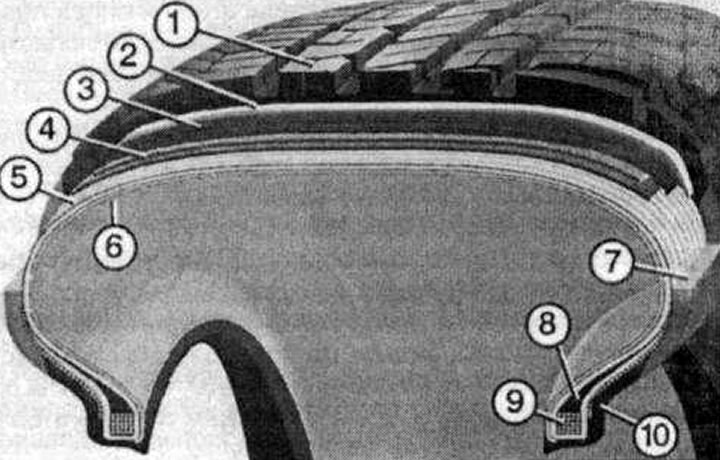

Multilayer tire for passenger car: 1 - tire properties depend on the treadmill, tread pattern and rubber composition, 2 - base (reduces rolling resistance), 3 - nylon bandage, 4 - layers of steel cord (increase vehicle stability while driving), 5 - frame (gives the tire shape and rigidity), 6 - sealing layer (gas-tight inner layer that replaces the chamber), 7 - sidewall (protects the frame from damage), 8 - core profile (promotes driving and steering precision), 9 - bead core (ensures a tight fit on the rim), 10 - bead reinforcement (improves the handling and stability of the car when driving).

The carcass, the appropriate rubber compound and the refined tread pattern make the tires currently produced a state-of-the-art product that makes an important contribution to the passive safety of the car. Tires carry the weight of the vehicle, take up small bumps from the side of the road, and transmit the forces that come from driving, braking and cornering. The service life of tires on the front wheels is from 50 to 60 thousand km. However, even if the car is not used intensively, tires need to be changed after seven to eight years, since the rubber compound decomposes over time.

Tires and rims (excerpt)

| Tire size | Wheel size | Pressing depth |

| 195/65 R15 | 7Jx15 | 45 mm |

| 215/55 R16Y | 7Jx16 | 45 mm |

Wheels for A4

Refer to your vehicle documentation for information on which tire and wheel sizes are allowed for your vehicle. The following combinations are fitted as standard: 7Jx15 lightweight forged aluminum wheels with 195/65 R15 tires or 7Jx16 m cast aluminum wheels with 215/55 R16Y tyres. Sixteen or seventeen inch light alloy wheels of various designs are available as special equipment. If you want to mount other tires or rims, make a corresponding note in the inspection for the admission of motor vehicles to operation. If the vehicle is equipped with a navigation system, this system must be calibrated in a workshop when the tire format is changed.

Ultralight tires

Ultralight tires use aramid fibers instead of steel inserts. Aramid is a polymer that is six times lighter than steel. At the same time, the tensile strength of aramid exceeds steel by about ten times. In addition, when using this material, the thickness of the outer wall of the tire is reduced by ten percent. The ultra-light tire 195/65 R 15 is about three kilograms lighter than a conventional tyre. First, it saves fuel. Secondly, by reducing the rotating masses, it is possible to reduce the frequency of regulation of the anti-lock system, and this, in turn, reduces the braking distance on slippery roads. And one more advantage of aramid tires: they are easier to restore, since polymer materials do not rust.

Wheel disks

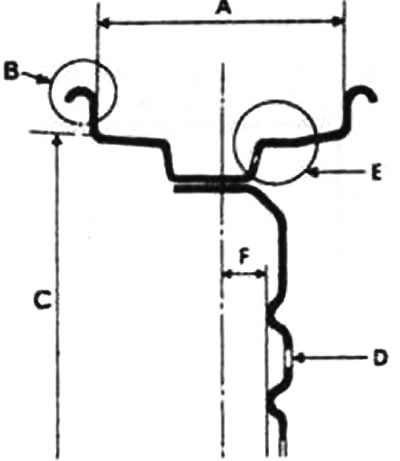

The size of the rim in accordance with the regulations is always indicated in inches. For example, the designation 7Jx 15 means a deep rim (X) 7 inches wide and 15 inches in diameter. The letter J denotes the shape of the rim flange. A feature of a deep rim is that to improve the fit of the tire, it has an annular protrusion on the landing shelf (hump). When moving quickly along a curve, the hump prevents the bead of the tire from being pushed out of the landing shelf into the recess.

Wheel dimensions: A - width in inches, B - bead height in inches, C - bore diameter in inches, D - number of holes, E - combined hump, F - pressing depth.

The most important tire parameters

On the sidewall of the tire there is a series of numbers and letters with which the manufacturer encodes the required parameters of the tire. Of course, the driver is primarily interested in tire size. 195/65 K 15, for example, means that the width of the tire's cross section is 195 mm. The second number is used to indicate the ratio between the height and width of the tire. In our example, this ratio is 65 percent. The smaller this ratio, the flatter and wider the tire is. The letter R stands for radial tires, the number that comes after this letter determines the diameter of the rim in inches.

Tire sidewall details: When buying a tire, pay attention to the data that is available on its sidewall. The new tire must fit the rim.

Maximum allowable speed

Another letter indicates the maximum allowable speed. For example, a tire with the letter S is designed for speeds up to 180 km/h, while a tire with the designation T is designed for top speeds up to 190 km/h. Accordingly, H - 210 km / h, Y - 300 km / h. If you use conventional tires for driving on muddy and snowy roads in winter, let off the gas earlier, as the maximum speed for a tire with the Q designation is only 160 km/h.

Date of manufacture and mark of conformity to UNECE quality standards

The date of manufacture can be determined by a three-digit number. Starting with the 1990 production year, this number is followed by a small triangle. For example, the number 187 indicates that the tire was produced in week 18, 1997. Tires manufactured after October 1, 1998 must have an ECE compliance number on the sidewall. This number indicates that the tire meets the quality standards of the United Nations Economic Commission for Europe. Tires manufactured after December 1999 are marked with a four-digit date of manufacture. For example, the number 0901 means that the tire was produced in the 9th production week of 2001.

Quality mark: capital letter 4 and a number indicating the country of origin, e.g. 1 for Germany or 4 for the Netherlands

Winter tires - special tires for driving on snowy and icy roads

Winter tires roll on snow and ice more reliably than summer tires. Winter tires are made from a special rubber compound with a high content of natural rubber, at temperatures below seven degrees they provide better grip on the road (both dry and wet). However, for good transmission of engine energy and braking force, the tread height must be at least 4 millimeters. All four wheels must be fitted with winter tires as the combination of summer and winter tires can be hazardous.

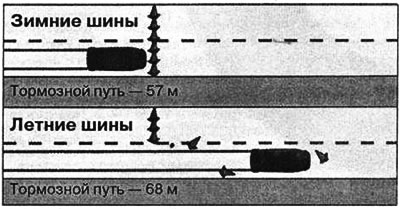

Ice-lock braking (speed 30 km/h): Comparison of braking patterns with summer and winter tires (car without anti-lock system)

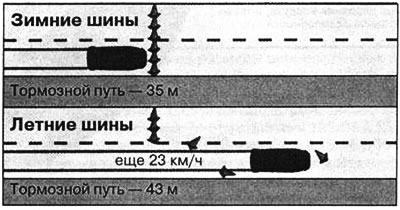

ABS braking on a snowy road (speed 50 km/h): Comparison of braking patterns with summer and winter tires (car with anti-lock system)

Mounting winter tires on rims

For winter use, a narrow tire is enough. The money saved on this is better spent on the purchase of a second set of suitable rims. Changing tires in spring and autumn will cost you much more in the long run.

The field of each wheel mounting must be balanced. Increase tire pressure by 0.2 bar. If the permissible speed for winter tires (up to 160 km/h) below the maximum speed of your vehicle, as a reminder, stick it in your field of vision (but not on the windshield) relevant note.

Visitor comments