Warning: Description of operations and instructions related to manual transmission and AT at the same time are given in subsection Removal and installation of manual transmission for turbo diesel engines (TDI).

This subsection describes only the differences that are relevant to AT.

1. Hang the engine from the cylinder head using a crane.

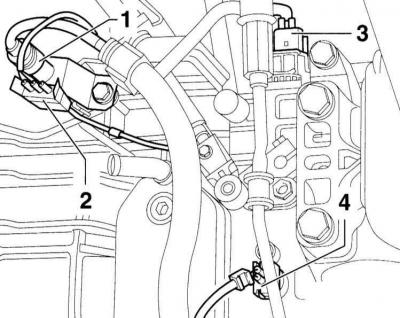

2. Disconnect the plug connection at AT, disconnect the cable guide.

- 1 solenoid valve sensor (10-pin)

- 2 speed sensor

- 3 multifunctional switch

- 4 transmission speed sensor

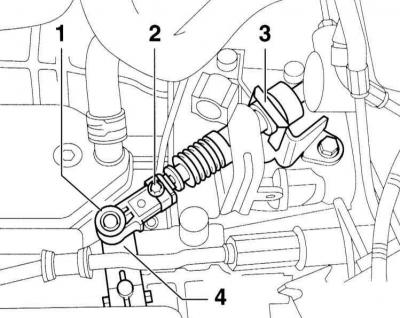

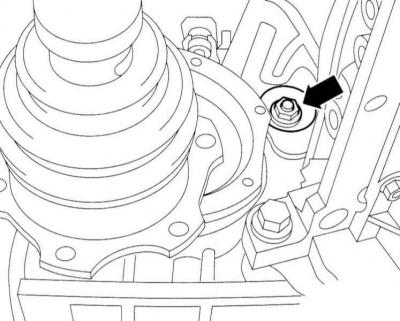

3. Use a screwdriver to pry out the shift lever (1) at the lever (4). Remove the retaining clip (3) at the support. Remove the shifter rod from the gearbox and take it aside.

Warning: Bolt (2) should not be turned away.

4. Turn away bolts of fastening and remove the holder of the submitting pipeline of the pump of the hydraulic booster.

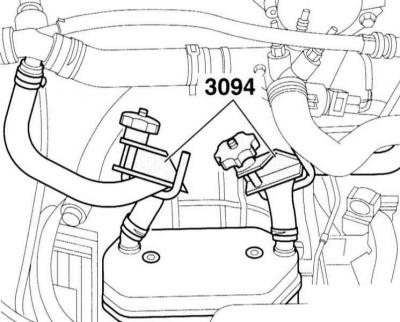

5. Clamp the ATF cooler hoses, for example, with the VW–3094 or HAZET–4590 tool. Loosen the clamps and remove the hoses.

Warning: Collect leaked oil with a rag.

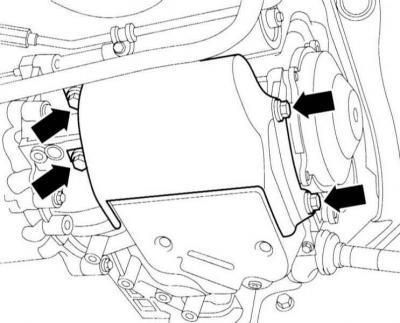

6. Loosen the mounting bolts and remove the shield (arrows in the illustration).

7. Remove the plug from the hole in the torque converter cover. Loosen 3 nuts and disconnect (arrow on accompanying illustration) converter from the clutch disc. Turn the engine head on the crankshaft pulley to the right so that the nuts are in the hole.

Warning: The torque converter is located between the engine and gearbox and is a fluid coupling.

8. Remove AT by analogy with manual transmission (Removal and installation of manual transmission).

Warning: When removing the AT from the engine, press the converter out of the driven disk. Protect the AT converter from falling out by placing a clamping device at the box casing and clamping it. If such a device is not supplied, when removing the box, make sure that the converter does not slip out of the box.

Installation

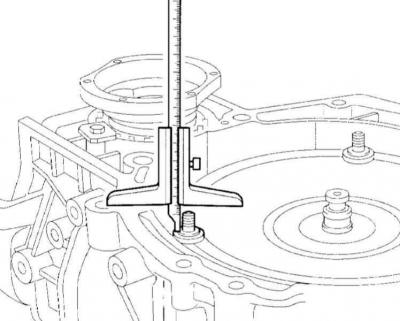

9. Before installing AT, measure the distance between the box flange and the thrust surface at the bottom of the threaded pin. It should be about 22 mm. If the specified distance is 10 mm, the transducer is not inserted correctly. In this case, carefully turn the transducer so that it slides down.

Warning: If the converter is installed incorrectly, the driven disk is destroyed when the box is installed.

10. Further installation is carried out in the reverse order of removal. Additionally, please note the following.

11. Use only original nuts to mount the transducer. The converter is attached to the driven disk with a torque of 60 Nm.

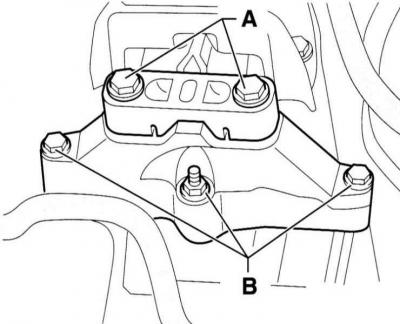

12. Replace the box mounting bolts. Fasten the bolts with the torques shown in the illustration.

13. Adjust the shift rod.

14. Check the ATF level in the final drive and in the box.

Visitor comments