Warning: Do not use open flames near the work area, do not smoke or hold any objects that are very hot. There is a danger of an accident! Keep a fire extinguisher ready.

Warning: Make sure the workplace is well ventilated. Fuel vapors are poisonous.

Warning: The fuel system is under pressure. When the system is opened, fuel can escape under pressure. Collect the fuel with a rag. Wear protective goggles.

Verification conditions: The battery must be fully charged, the voltage must not be less than 11.5 V.

Checking the voltage supply

1. Check the No. 28 fuel pump fuse. Replace defective fuse.

2. Briefly turn on the starter. The fuel pump should work, which is short-term (about 1 s) should be heard. With a high level of ambient noise, you can ask an assistant to listen.

3. If the pump does not work, connect the remote control.

4. Press the remote control switch. If the pump is now running, check the fuel pump relay.

If the pump is not working, proceed as follows:

5. Tilt back the rear seat and unscrew the cover of the reserve sensor and fuel pump.

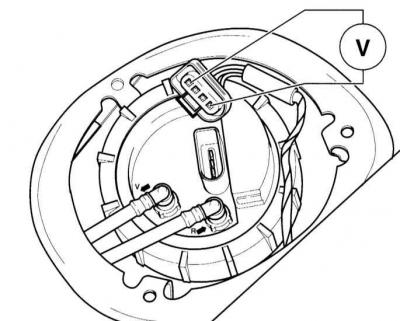

6. Disconnect the reserve sensor and fuel pump connector.

7. Connect a diode test lamp or a voltmeter to both external contacts of the plug.

8. Turn on the remote control. The meter should show battery voltage (about 12 V), otherwise there is a break in the wires, which should be identified using the electrical circuit and repaired.

9. If the gauge shows battery voltage, remove the fuel reserve sensor.

10. Check if the flange and the fuel pump are connected by electrical wires and if there is a good connection contact. Check with an ohmmeter and auxiliary wires for an open in the wires between the sensor housing and the fuel pump and repair if necessary.

11. If there is no open, replace the fuel pump.

12. Install the fuel pump and reserve sensor, connect the electrical wires.

Checking pump performance

1. Remove the fuel tank cap to relieve fuel pressure.

Warning: The fuel system is under pressure! Before opening the hose connections, place a thick rag on it. Then carefully open the hose and release the pressure. Use protective goggles when doing this.

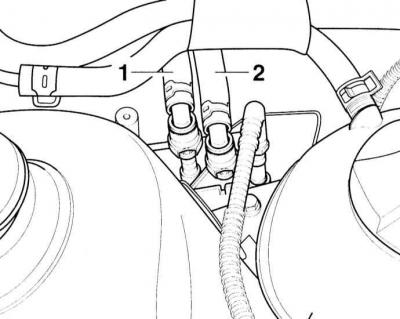

2. Disconnect the fuel return hose at the fuel rail by pushing in the quick release release button. 1 - fuel supply pipeline.

3. Connect an auxiliary hose with an intermediate element to the fuel return line from the engine and lower it into a measuring container.

4. Attach a voltmeter to the battery.

5. Press the remote control switch within 15 seconds. In this case, read the indicated battery voltage and write it down.

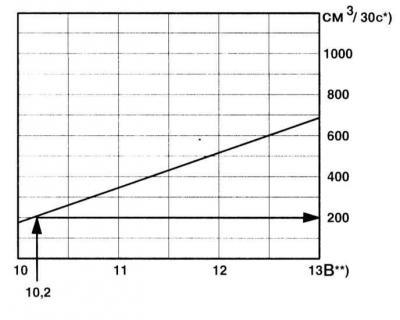

6. Compare the pump output with the required value on the diagram.

Example: During the test, the battery voltage is 12.5V. Since the voltage at the fuel pump is 2V less than the battery voltage, the voltage at the fuel pump is 10.5V (12.5 – 2 = 10.5). This voltage corresponds to a pump output of about 130 cm3 /15 s.

*) Minimum performance, see3 /15 s.

**) Fuel pump voltage with engine off and pump running (about 2V less than the battery voltage).

7. If the supply voltage is OK, but the performance is still low, check the fuel lines for damage or blockages.

8. Check if the fuel filter is clogged. To do this, repeat the performance test with a new fuel filter.

9. If the minimum performance is still not achieved, remove the fuel supply unit and check if the filter screen is clogged. Clean the mesh if necessary.

10. If no fault found, check fuel pump check valve (service station work).

Warning: If the minimum performance is reached, but a fuel supply fault is still suspected (e.g. intermittent feed stop), check the current consumption of the pump with an ammeter. Required value: max. 8 A. If the current is greater, replace the fuel pump.

Warning: In case of intermittent interruptions in the operation of the fuel system, it is possible to carry out a check while the vehicle is moving. This requires an assistant.

11. Remove the remote control and replace the No. 28 fuse.

12. Screw on the fuel tank cap.

13. Replace the back seat.

Visitor comments