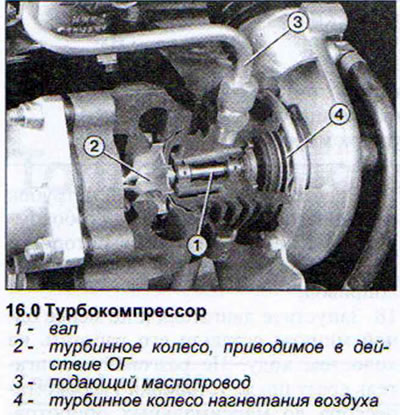

The turbocharger consists of two turbine wheels mounted on the same shaft. Exhaust gases enter one wheel, powering this wheel. Simultaneously with the rotation of the first wheel, the second one also rotates, which pumps atmospheric air into the combustion chambers (see illustration 16.0).

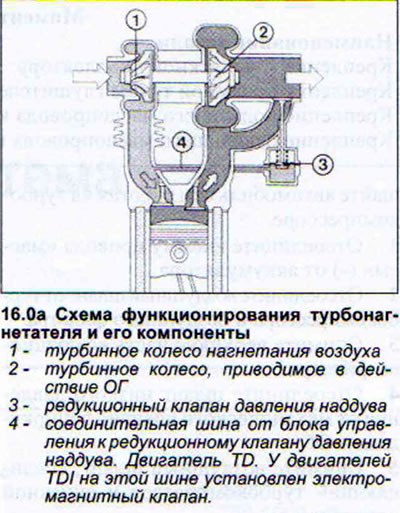

With this functioning of the turbocharger, with an increase in its speed, excess air will be injected into the combustion chambers and the boost pressure will become such that the engine cannot withstand it (see illustration 16.0a).

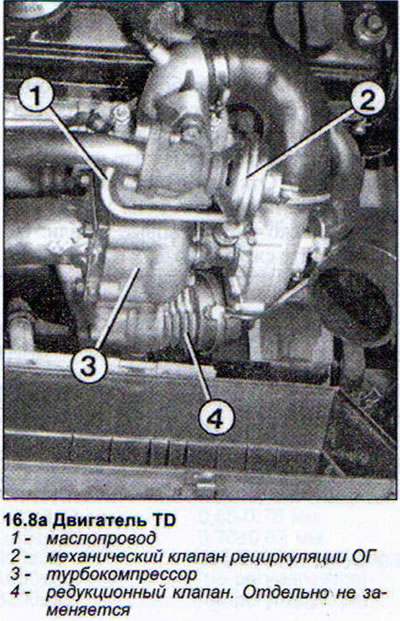

To avoid this situation, TD engines are fitted with a boost pressure reducing valve. This valve opens allowing only part of the exhaust gas to reach the compressor turbine wheel and thus keeping the boost pressure within 0.83 bar.

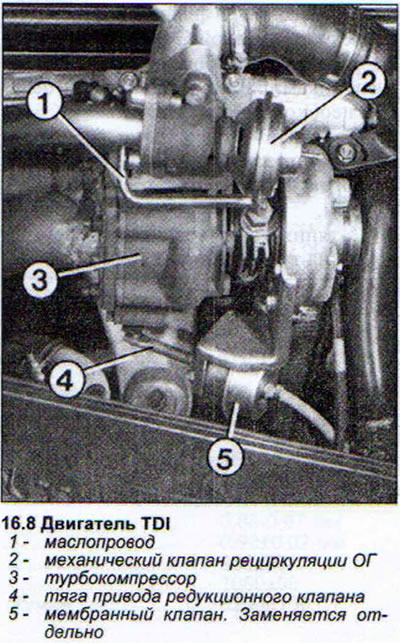

The TDI engine is also equipped with a governor. However, in this case the regulator functions differently than on TD engines and limits the boost air pressure. This is done using a solenoid valve located at the rear of the engine compartment on the right side. This valve, through the rod from the diaphragm valve, opens the pressure reducing valve, reducing the boost air pressure. The solenoid valve is controlled by the power system control unit according to information from the intake manifold pressure sensor. The intake manifold pressure sensor is connected by a thin hose to the intercooler (charge air cooler). Thus, the boost air pressure regulator is able to compensate for the decrease in air density in high altitude areas.

Boost air pressure regulator solenoid valve - check

1. Make sure the hoses attached to the valve are not tangled.

2. Measure the internal resistance of the valve. To do this, disconnect the valve plug.

3. Connect a sensitive ohmmeter to both pins of the plug. It should show 24-28 ohms. Otherwise, the boost air pressure control solenoid valve is defective and must be replaced.

4. Check the power supply to the solenoid valve. To do this, connect a voltmeter to terminal 2 of the connector and to «mass» (see illustration).

5. Turn on the ignition. The voltmeter should show battery voltage. Otherwise, there is a break in the power wire.

The procedure for checking the pressure sensor in the intake manifold is indicated in the appropriate chapter.

Boost air pressure control diaphragm valve - check

6. Warm up the engine to operating temperature.

7. Check the boost air pressure control solenoid valve plug.

8. Start the engine and increase its speed to maximum. The pressure reducing valve actuator rod from the diaphragm valve must move (see illustration).

Note: Switching off the engine immediately after a long drive at full load is harmful to the turbocharger. Such handling of the turbocharger can lead to «coking» supercharger. The shaft bearing next to the turbine wheel, due to the sudden accumulation of hot air, heats up to such an extent that all the grease in the bearing burns out and sticks to the rubbing surfaces. If the engine is stopped in this way continuously, the turbocharger will not last long. Therefore, after a long trip in mode «Full load» it is recommended not to turn off the engine, but to let it idle for a while.

Visitor comments