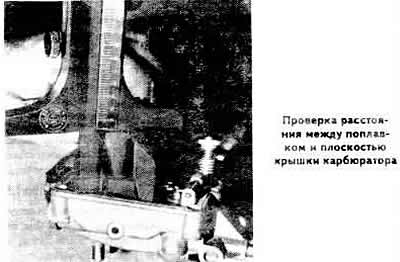

Checking the fuel level in the float chambers

Remove the carburetor cover and turn it over.

Measure the distance between the plane of the carburetor cover and the lower point of the floats, which for the 1st chamber should be within 28±0.5 mm, for the 2nd chamber - 30±0.5 mm. If it does not correspond to this, set the desired size by bending the tongues of the float levers.

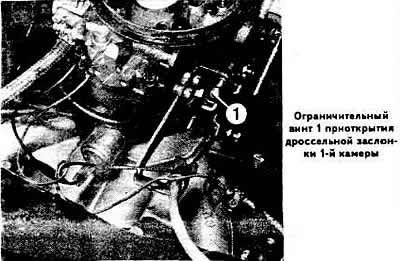

Throttle opening adjustment of the 1st chamber

The position of the restrictive screw for slightly opening the throttle valve of the 1st chamber was adjusted during assembly and cannot be changed. If the position of the screw is accidentally disturbed, it can be restored as follows:

- unscrew screw 1 (see photo) so that it moves away from the curly sector;

- carefully tighten the screw until it touches the sector;

- tighten the screw another ¼ turn;

- adjust engine idle.

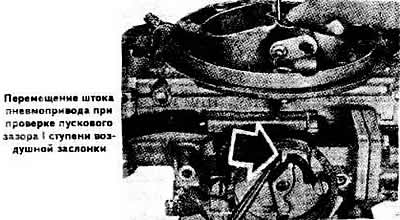

Checking and adjusting the starting clearance of the 1st stage air damper

Remove starter cover.

Close the air damper.

Push in the movable rod of the air damper until it stops.

By lightly pressing from top to bottom, select the gaps in the system of levers and rods.

In this position, using the rod or tail of a thin drill, measure the starting gap of the first stage of the air damper, which should be within 3.15±0.15 mm.

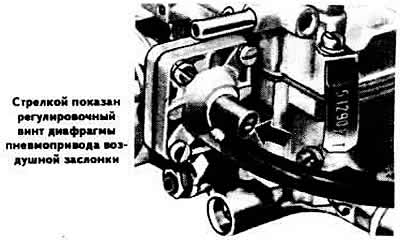

Adjust, if necessary, with the adjusting screw of the diaphragm of the pneumatic actuator of the air damper (see photo) nominal starting gap and lock the adjusting screw.

Adjustment of the starting clearance of the 1st throttle stage

Disconnect the negative cable from the battery.

Remove the carburetor from the engine.

Close the air damper.

Using a rod or shank of a thin drill, measure the starting clearance of the first throttle stage, which should be within 0.65±0.05 mm.

If necessary, adjust the gap by turning the adjusting screw «b» (see photo), and then adjust the idle speed of the engine.

Adjustment of the automatic starter

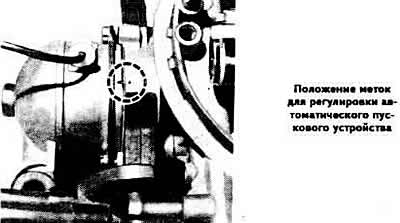

There are marks on the carburetor body and the starting device body, which, when the starting device is in the correct position, must be aligned, as shown in the circle in the photo.

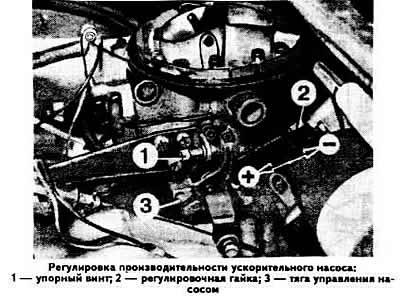

Accelerator pump performance test

Disconnect the wire from the negative battery terminal.

Remove carburetor.

Place a beaker with a funnel under the carburetor.

Ten times quickly and fully open the throttle and measure the amount of fuel flowing out of the beaker, which should be within 13±1.5 cm3.

To adjust, turn adjusting nut 2 (see photo) in the direction of the sign «+», to increase pump performance, and in the direction of the sign «-», to reduce it.

After installing the carburetor, adjust the idle speed of the engine.

Engine idle adjustment

The engine idle adjustment is made ON a warm engine (oil temperature not less than 60°C), with the air damper fully open, with the ignition timing correctly set and the clearances in the valve drive mechanism adjusted.

Using a connected tachometer, check the engine speed, which should be within 900-1000 rpm.

If necessary, the adjusting screw of the amount of the mixture (see photo) achieve the crankshaft speed within the specified limits.

Connect the gas analyzer in accordance with the instruction manual.

Switch off current consumers.

Disconnect the air supply hose from the air filter on the cylinder head cover and close the hose hole with a plug on the side of the air filter.

Remove the plug of the quality adjusting screw (composition) mixtures.

Adjust the CO content in the exhaust gases within 1.0-2.0% by turning the adjusting screw (shown by the arrow in the photo); during adjustment, the cooling radiator fan should not rotate.

After adjustment, lock the adjusting screw and close it with a plug.

Visitor comments