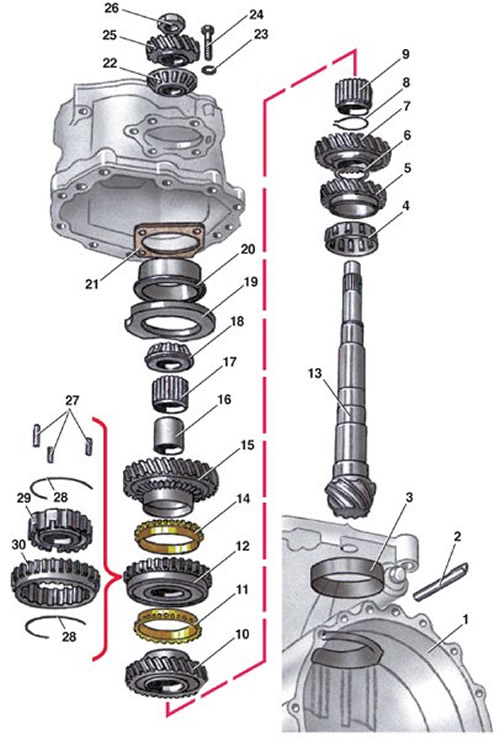

Type 013 gearbox output shaft

- 1 - clutch housing;

- 2 - pin;

- 3 - the outer ring of the bearing;

- 4 - roller bearing;

- 5 - gear wheel of the 4th gear;

- 6 - retaining ring;

- 7 - 3rd gear gear;

- 8 - retaining ring;

- 9 - needle bearing 2nd gear;

- 10 - 2nd gear gear;

- 11 - synchronizer blocking ring;

- 12 - synchronizer;

- 13 - secondary shaft;

- 14 - synchronizer blocking ring;

- 15 - 1st gear gear;

- 16 - the inner ring of the needle bearing;

- 17 - needle bearing 1st gear;

- 18 - roller bearing inner ring;

- 19 - locking plate;

- 20 - the outer ring of the bearing;

- 21 - gasket;

- 22 - the outer ring of the roller bearing;

- 23 - washer;

- 24 - bolt;

- 25 - gear wheel of the 5th gear;

- 26 - nut;

- 27 - cracker;

- 28 - spring;

- 29 - hub;

- 30 - clutch

Disassembly

1. Press the remaining inner race of the output shaft rear tapered roller bearing and gear 15 1st gear (applying force to the 1st gear).

2. Remove needle bearing 17 and mark it.

3. Mark the position of the coupling and synchronizer hub relative to the shaft.

4. Press the synchronizer 12 complete with blocking rings 11 and 14 and gear 10 of the 2nd gear (applying force to the 2nd gear).

5. Remove the needle bearing 9 of the 2nd gear and mark it.

6. Remove retaining ring 8 and compress gear 7 of 3rd gear.

7. Remove retaining ring 6.

8. Press the gear wheel 5 of the 4th gear and remove the front roller bearing 4 of the secondary shaft.

Assembly

1. Install the front roller bearing 4 of the secondary shaft on the output shaft.

2. Orient gear 5 of the 4th gear with a wide shoulder towards the main gear and press it onto the shaft until it stops, preheating it to a temperature of 120°C in any way possible, but without using an open flame.

3. Select the thickness of the retaining ring 6 so as to maximize the axial clearance between it and the 4th gear. Spare parts are supplied with retaining rings with a thickness of 2.35; 2.38; 2.41; 2.44 and 2.47 mm.

4. Orient gear 7 of the 3rd gear with a wide shoulder towards the gear of the 4th gear and install it on the shaft until it stops.

5. Select the thickness of the retaining ring so as to maximize the axial clearance between it and the 3rd gear. Install the circlip on the shaft. Retaining rings 1.50 and 1.60 mm thick are supplied as spare parts. 6. Install needle bearing 9 and pinion 10 2nd gear.

7. Install the synchronizer 12 3rd and 4th gear assembly with blocking rings in accordance with the marks made earlier.

8. Install needle bearing 17 and pinion 15 1st gear.

9. Press on the inner race 18 of the rear tapered roller bearing of the secondary shaft.

Visitor comments