Installing the main bearing cap No. 4 with an insert with a thrust half ring

The axial movement of the crankshaft is selected on the fourth support, the bearing shells of which have two thrust collars.

Pick up the main bearing caps with liners and install them on the bed of the block. Tighten the cap bolts to 6.5 kgf·m.

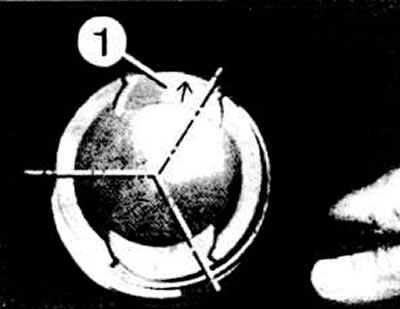

Install three piston rings into the corresponding grooves in the pistons, placing them locks through 120° (see photo).

When installing the piston rings in the grooves, the locks of the rings must be located relative to each other at an angle of 120°. Arrow 1 shows the direction of installation of the pistons (towards the camshaft drive)

Orient the piston ring locks forward or backward while driving. There is a mark on the lower compression and oil scraper rings «tor» or «oben» («top»), which should be facing up when installing the ring in the wire rod.

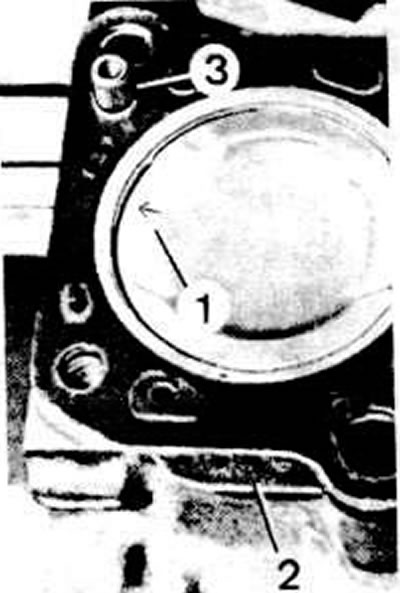

Installing the pistons with a mounting sleeve to compress the piston rings

Install the pistons, orienting the arrow squeezed out on the bottom of the piston forward in the direction of the car (towards the camshaft drive).

Lubricate the pistons and piston rings with engine oil, compress the piston rings in the grooves of the appropriate mounting sleeve, and insert the pistons with the connecting rods into the cylinders.

Installation of pistons with connecting rods and cylinders: 1 - the arrow should be directed towards the camshaft drive; 2 - the mark on the cylinder head gasket must be directed to the plane of the head; 3 - dowel pin for proper installation of the cylinder head and head gasket

Install the connecting rod bearings and connecting rod caps in accordance with the marks made during disassembly, if worn bearings are used.

Install the connecting rods and caps on the crankshaft journals, with the sags on the caps directed towards the intermediate shaft.

Lightly tighten the nuts of the connecting rod bolts, then tighten them finally to the required torque.

Install the rear oil seal holder with a new cardboard gasket. Using tool 2003/1, press the oil seal into the holder.

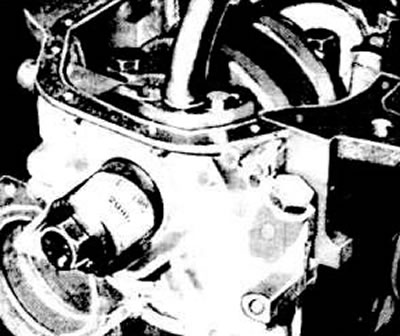

Pressing in the front crankshaft oil seal

Install the flywheel.

Installation of a back epiploon of a cranked shaft

Install a new front oil seal and crankshaft retainer gasket. Install the oil pump holder so that the pinion lugs engage with the flats on the crankshaft.

Install the oil pickup tube.

Install the oil pan with a new gasket.

Install the water pump, thermostat and thermostat housing.

Install the cylinder head.

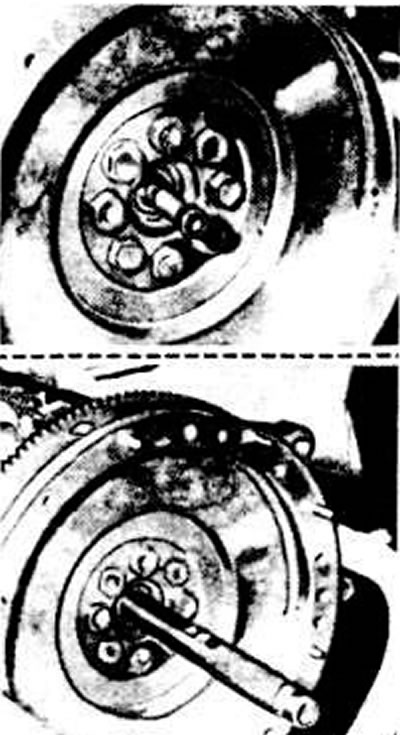

Removal and installation of the bearing of a primary shaft of a transmission. Top: Removing a bearing with an external puller. Bottom: Installing a bearing with a mandrel

Install the camshaft drive belt.

Visitor comments